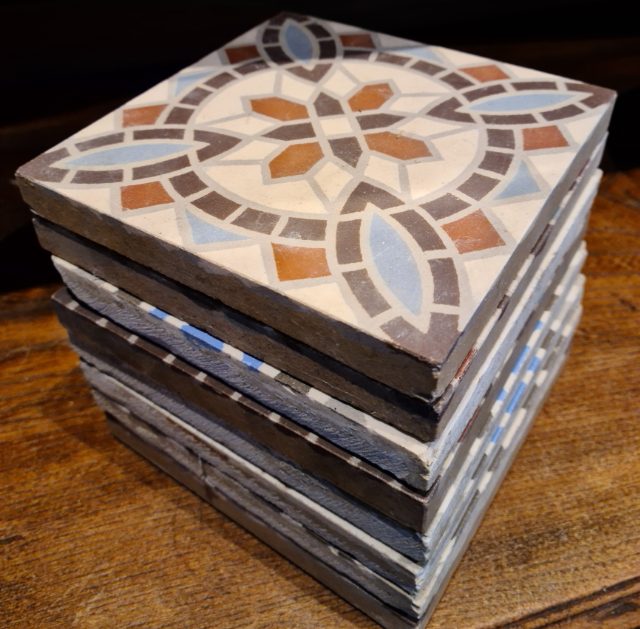

Photo: Impermo

|

A mixture of marble powder and colored cement is poured the motif sections of a mold. The grid keeps the different colors separated so that the motif of the tile can be formed. After removing the grid, the tile is immediately sprinkled with a mixture of sand and cement. When the mold is completely filled, a stamp is used to put the manufacturer’s trade mark on the back of tile. The tile is pressed and then removed from the mold. Finally, after resting for 24 hours, the tiles are moisturized in water for several hours and left to dry for several more weeks. |

|

Around 1900 the ceramic and cement tiles were made in a similar way. Also for the production of the ceramic tile a frame was used but it was filled with colored dusty clay (low moisture content) . After removing the frame, backing clay was added and pressed under huge pressure. After pressing the tile, the tile was baked at a high temperature (>1200°C) . This makes the ceramic tile harder (indestructible), the surface is smoother and slightly more shiny than the cement tile. |

Photo: tile press from the Guillot Hemiksem factory Belgium (photo: Mario Baeck)

|

Today new ceramic pattern tiles are made by machine. The motif is printed on the tile like a photo. This means that the current ceramic tiles are a lot thinner than antique encaustic ones (1.4 cm). The antique tile is filled with colored clay to 1/3 of the tile thickness. So the colors have remained just as vibrant, even after a century of use. Unfortunately the traditional production process of these antique ceramic tiles is completely vanished. mySTILES only sells ceramic tiles that are manufactured according to the old production process. |